Manufacturing Processes : Mastery is a true mark of quality.

Our metallurgical workshops and manufacturing processes, located in Vendée, bring together comprehensive expertise certified to ISO 9001 standards from laser cutting to welding and fabrication, including bending, passivation, polishing, and quality control.

In this article, we invite you to discover AMIAUD, a metallurgical company, and the key stages of our manufacturing processes, which ensure the quality and durability of our parts.

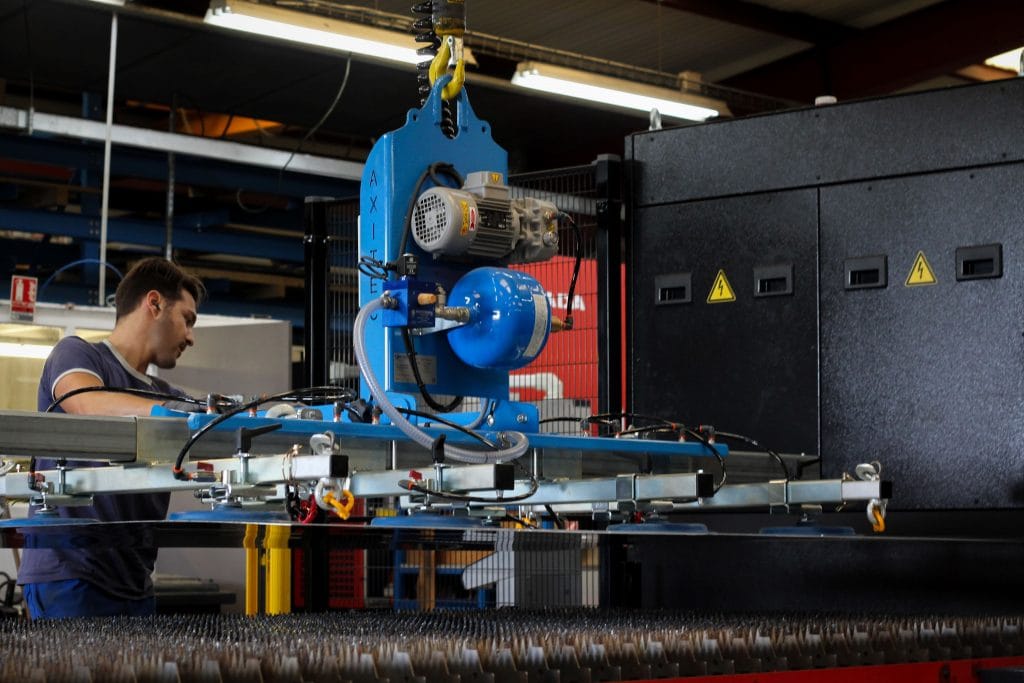

Laser Cutting : Precision in the Service of Performance

Laser cutting is the starting point of manufacturing at AMIAUD.

Thanks to our state-of-the-art equipment, we cut stainless steel, steel, aluminum, brass, and copper with high precision, meeting the most demanding tolerances.

This process ensures clean edges, consistent quality, and optimal preparation for subsequent bending and assembly operations of industrial parts.

Folding : Shaping the Material

Bending transforms sheet metal into a three-dimensional shape.

Our CNC press brakes ensure perfect repeatability and millimetric precision, even for complex series.

Industrial bending requires complete control of the material and bending radius, guaranteeing a final result that meets our clients’ mechanical and aesthetic requirements.

Welding and Fabrication : Assembling with Precision

Welding and fabrication are at the heart of AMIAUD’s expertise.

Our qualified welders produce strong and durable assemblies using various processes (TIG welding, MIG welding, etc.).

Each weld is carefully inspected to ensure strength, durability, and the visual quality of the manufactured parts.

This know-how is essential for producing metal components designed for demanding environments such as marine and industrial applications.

Additional Operations : Drilling, Cutting, Bending, and Threading

Our metallurgical workshops in Vendée integrate all the operations required for the production of your parts, with all our home-made expertise :

• Drilling, tapping, and threading

• Cutting and bending

• Preparation and deburring

This integration allows us to be fully autonomous in production, reduce lead times, and ensure complete traceability for every project.

Passivation and Polishing : Finishing and Protection

Because durability is part of our DNA, we pay special attention to finishing.

Passivation enhances the corrosion resistance of parts, while polishing perfects the surface finish and overall appearance of the products.

These finishing treatments ensure a result that is both technically precise and aesthetically refined, reflecting AMIAUD’s commitment to excellence.

Assembly, Quality Control, and Shipping : Precision Every Step of the Way

Before shipping, each product undergoes precise assembly and rigorous quality control.

Our teams inspect every dimension, weld, and finish to ensure full compliance with the specifications.

Finally, the products are carefully packaged and shipped on time, guaranteeing flawless delivery to our customers.

AMIAUD : Integrated Manufacturing in the Service of Quality

From laser cutting to final inspection, every step is designed to ensure quality, reliability, and performance.

Our mastery of all manufacturing processes enables us to support professionals in the industrial, marine, and fishing sectors with products available through AMIAUD PÊCHE offering tailored, durable solutions proudly made in France.